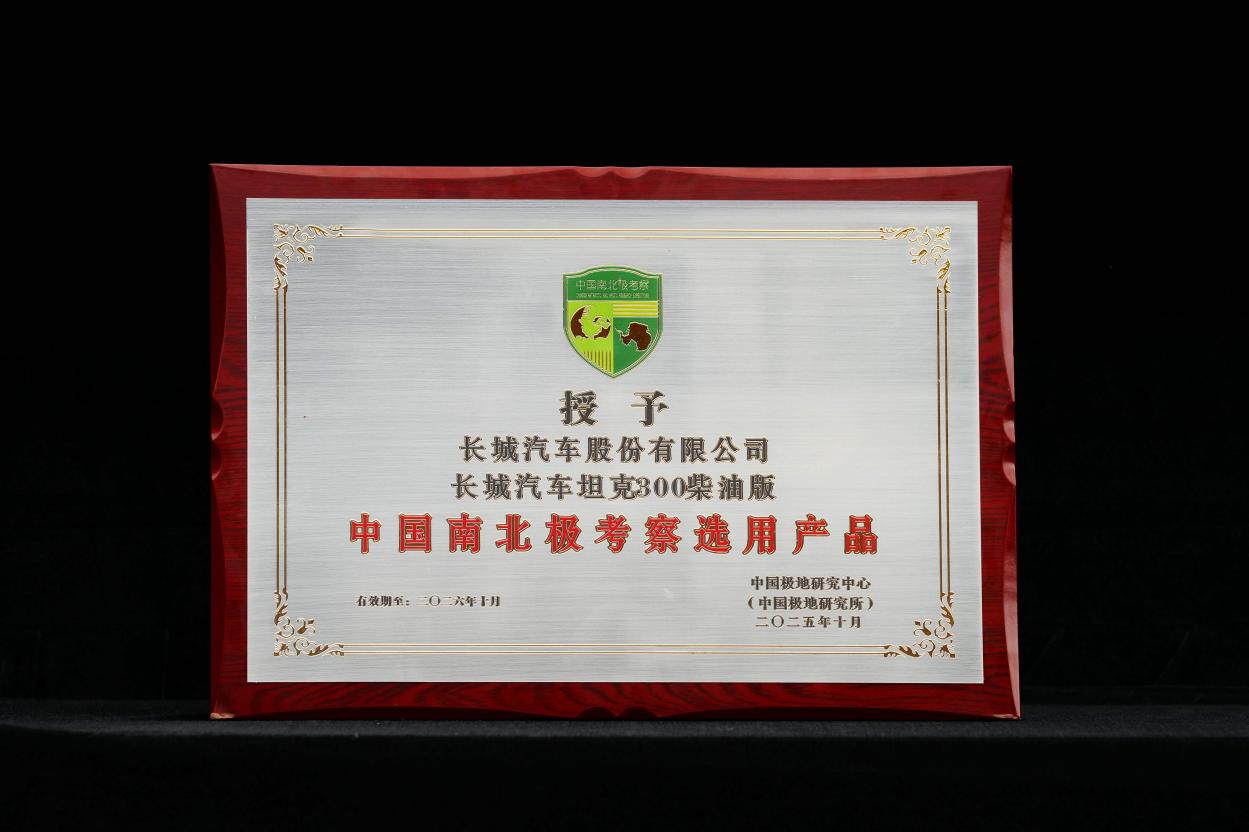

On October 11, 2025, at the Great Wall Motor Technology Center in Baoding, the signing ceremony between Great Wall Motors and the China Polar Research Center connected China's private automobile companies with the country's polar scientific research.

This signing marks the entry of another private manufacturing force into the national polar equipment support system, and writes a new footnote for the technological strength and value positioning of Chinese automobile brands.

From corporate quality to national recognition

The extreme Antarctic environment places unparalleled challenges on mechanical equipment. Frequent strong winds and blizzards, along with a road surface crisscrossed with ice cracks, hidden ditches, and a mix of gravel and frozen soil, place stringent demands on vehicle performance. The Polar Research Center of China, the leading authority on polar expedition equipment, selected Great Wall Motors as a key partner based on key requirements such as the vehicle's powertrain's low-temperature stability, chassis impact resistance, and oil adaptability to extreme environments.

Behind this recognition lies Great Wall Motors' commitment to "reliable quality." At the signing ceremony, Great Wall Motors Vice President Liu Yanzhao stated, "The recognition from the China Polar Research Center has become a heavy responsibility." Unlike some previous companies showcasing modified vehicles, the Tank 300 diesel version deployed in Antarctica is a production model, unmodified. It will directly handle practical support tasks such as commuting personnel and transporting supplies during the Great Wall Station expedition. This "original factory" reliability is rare among vehicles used in polar research expeditions worldwide.

Furthermore, Great Wall Motors technicians will participate in polar scientific expeditions for the first time. This arrangement establishes a closed loop of "on-site support, data feedback, and technical optimization." During the expedition, technicians must not only ensure reliable vehicle operation but also accurately record key data such as power output and chassis response in extreme environments, providing a basis for subsequent polar equipment development.

On the day of the signing, experts from the China Polar Research Center visited Great Wall Motors' core R&D laboratory. In the environmental wind tunnel test chamber, a Tank 300 was undergoing extreme cold environment testing. After more than ten hours of activating the blizzard simulation system, the vehicle successfully completed key operations such as one-touch start, defrosting, and heating. Each stable operation vividly demonstrated its ability to withstand polar missions.

Polar confidence supported by a full-scenario verification system

The Tank 300 diesel version's boldness in mass production and its attempt to challenge the Antarctic is fueled by Great Wall Motors' multi-year global, full-scenario testing and verification system. With a total investment of approximately 1 billion yuan, this system encompasses a full range of capabilities, from environmental simulation to safety verification. Its high-altitude test chamber and environmental wind tunnel are the first of their kind among Chinese domestic automakers, filling a gap in extreme environment simulation testing for domestic automakers.

Great Wall Motors' environmental wind tunnel test chamber accurately replicates extreme global climate conditions, with a temperature control range of -40°C to 60°C and a humidity adjustment range of 5% to 95% RH, encompassing temperatures and humidity conditions ranging from the Antarctic ice sheet to tropical deserts. The wind tunnel nozzles are adjustable, with a maximum area of 8 square meters adjustable to 6.4 square meters, achieving wind speeds of up to 250 km/h and accurately simulating severe Antarctic blizzards. The full-spectrum sunlight simulation system adjusts light intensity and angle, and combined with the precipitation system, can simulate five rain qualities and four snow qualities, completely breaking the limitations of seasonal and regional testing.

The authority of this testing system stems from its rigorous qualifications and comprehensive capabilities. Great Wall Motors' laboratory has been accredited by China National Association of Testing Organizations (CNAS), and its testing site has received national accreditation. The data produced has international credibility and is recognized by laboratory accreditation bodies in over 40 countries and regions worldwide. The system covers multiple areas, including thermal management, emissions, and powertrain, with over 2,000 cumulative testing capabilities, forming a comprehensive testing matrix covering the entire vehicle development lifecycle.

The Tank 300 diesel version features targeted redundant design features to withstand the extreme demands of polar environments. To achieve single-shot starting in -35°C temperatures, the bearings are resin-coated and the piston skirts are graphite-coated, reducing engine friction by over 30%. A high-speed glow plug heats the cylinder to over 1000°C in just 3 seconds. A low-temperature-resistant, high-capacity starting battery provides stable power for the starting system. These features are standard on production models, demonstrating forward-thinking considerations.

Chassis reliability has been rigorously tested both in the laboratory and in real-world scenarios. The Tank 300 diesel engine has undergone over 30 bench tests, encompassing full-speed, full-load, and alternating-load conditions. It has accumulated 14,000 operating hours, equivalent to approximately 4.8 million kilometers. The longest single engine run exceeded 1,000 hours with no degradation.

In real-world scenarios, the vehicles underwent two winter and two summer calibration tests, ranging from the bitterly cold of Hailar and Heihe to the scorching heat of Turpan and the high altitude of the Kunlun Mountains. These extreme conditions fully honed the components. The diesel model alone logged 640,000 kilometers in endurance testing, equivalent to 1.81 million kilometers in user mileage.

Synchronization of corporate development and national strategy

The collaboration between Great Wall Motors and the Polar Research Center of China embodies the profound alignment between the development of private enterprises and national strategic needs. In polar research, a field crucial to national scientific research capabilities, equipment independence has always been a core goal, and Great Wall Motors' participation injects private manufacturing power into this process.

This collaborative model achieves a closed-loop innovation cycle, from technology R&D to scientific research applications, and then to civilian applications. The two parties are jointly conducting research and development and testing projects for Antarctic and Arctic research vehicles, focusing on key areas such as polar vehicle support and complete vehicle extreme cold validation, precisely aligning national scientific research needs with the company's R&D capabilities. Great Wall Motors technicians will participate in the expedition, providing real-time technical support and feeding polar operational data back to the R&D system. This first-hand information will become a valuable resource for optimizing the extreme performance of civilian vehicles.

For Chinese auto brands, this polar expedition holds immense value. For a long time, the international market has largely viewed Chinese cars as value-for-money vehicles. However, Great Wall Motors's commitment to Antarctica with mass-produced vehicles and the extreme environment testing it offers is rewriting this perception.

From a corporate strategic perspective, this collaboration aligns closely with Great Wall Motors' development strategy of "globalization, all-scenario, and all-motor." While the polar market is niche, its technological requirements match the highest standards of the global automotive industry. By participating in polar expeditions, Great Wall Motors is able to validate its products and technologies in the most demanding scenarios, accumulating experience for its global expansion. Furthermore, collaboration with the China Polar Research Center allows R&D to better meet the needs of all scenarios, continuously expanding the scope of its products' applicability.

As the Tank 300 diesel truck journeys to Antarctica, it carries not only scientific research materials and personnel, but also the technological confidence and value dreams of Chinese auto brands. On the polar ice sheet, it will stand alongside the Great Wall Station as a witness to the growth of China's auto industry, proclaiming to the world that Chinese vehicles are capable of challenging the world's harshest environments.