Under the wave of electrification and intelligence, people's definition of excellent cars is undergoing drastic changes, and the industry has ushered in a new ecological model after a century of linear development. "Software-defined cars" has become a consensus, computing power and data are deeply integrated into the steel body, and the transformation of future travel forms is quietly accelerating. However, behind the technological leap, a fundamental proposition always stands like a rock: How to ensure that every innovative breakthrough maintains the bottom line of quality and safety?

Against this backdrop, the 5th China Automotive Quality Technology Conference was held in Shenyang a few days ago. This Northeast industrial city is not only an important landmark of China's manufacturing industry, but also a strategic fulcrum of the BMW Group's global production network. The conference brought together nearly 600 industry experts, vehicle enterprise representatives, top suppliers and scholars from research institutions at home and abroad.

While many eyes are focused on the new challenges of automotive quality management in the digital age, the production base of the organizer, BMW Brilliance, has already outlined the clear outline of future intelligent manufacturing with its actions - the "zero defect" system driven by AI is laying the most reliable quality foundation for BMW's journey to the "new generation".

AI drives new standards in smart manufacturing

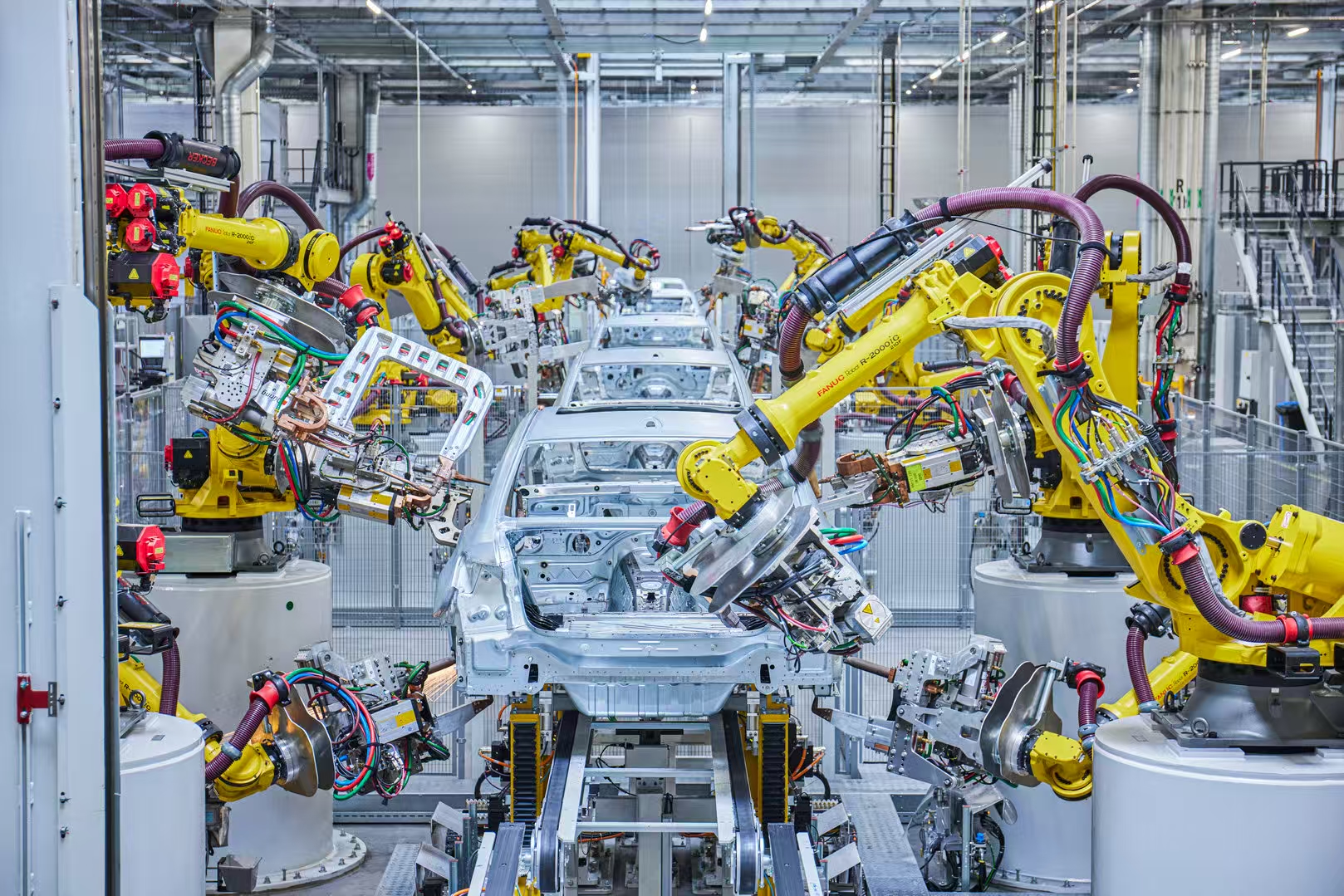

Stepping into the BMW Brilliance Shenyang production base, the pulse of intelligence is clearly felt. Here, AI is no longer a concept in the laboratory, but a practical measure deeply integrated into the manufacturing process. About 200 AI applications run in coordination in the factory, just like musicians in a precision symphony orchestra, playing the movement of efficiency and quality together.

The tentacles of this technology empowerment have extended to the 360-degree full-chain business. Starting from the source of R&D and design, AI simulation technology has been deeply involved: vehicle surface design simulation is more accurate and efficient, the thermal management solution of the power battery is repeatedly optimized in the virtual space, and the safety performance is continuously improved in data deduction. The seamless connection between virtual and reality has greatly shortened the R&D cycle, while significantly improving the reliability and safety of the product.

In the production line, AI is more intuitive. In the stamping workshop, the industry's first self-developed AI intelligent quality inspection system is like a tireless "eagle eye", screening the subtle defects of complex stamping parts. In the paint shop, the AI visual inspection system captures any tiny flaws on the paint surface with an accuracy that exceeds the limits of the human eye, and its detection accuracy is infinitely approaching 100%.

The application of these technologies has upgraded the traditional quality control model that relies on experience and manual sampling to real-time, full-scale, and intelligent process monitoring and prevention. More importantly, the in-depth application of AI in preventive maintenance, inventory logistics optimization and other links has effectively avoided potential production interruptions and resource waste, and implemented the concepts of "zero defects", "zero delays" and "zero waste" throughout the entire manufacturing process.

Defining the quality level of the "new generation"

Facing the upcoming "new generation" models, BMW is well aware that innovation does not stop at the product level, but is more deeply rooted in the ultimate commitment to quality. Dai Hexuan, President and CEO of BMW Brilliance Automotive Ltd., said at the conference: "There is no room for compromise in quality - it has been so in the past, it remains so today, and it will be adhered to in the future." This commitment has been internalized as the "zero defect" gene, running through every link of the entire value chain and the entire product life cycle.

In BMW's quality dictionary, "safety" is always the first core essence. When the industry is racing fiercely in the field of intelligent driving, BMW chooses to make "safety first" an insurmountable red line.

At present, China's automobile industry chain is very mature, and there is no shortage of leading companies in the fields of chips, smart driving, batteries, etc. It has gradually become the norm for overseas giants with deep roots in China to cooperate with them.

However, in the same cooperation, some OEMs choose to completely let go of their souls and "entrust their souls to others". However, BMW always holds the initiative in its own hands and adheres to the "bottom line" of quality.

For example, the China-exclusive intelligent driving assistance system developed in cooperation with Momenta is not a simple accumulation of popular functions, but a deep integration of BMW's more than 20 years of technological accumulation in the field of driving assistance into the system design, which minimizes driving risks and ensures that users can get a "safe and daring" experience. Behind this is the respect for the supremacy of life and the adherence to technological ethics.

In order to support the higher quality requirements of the "new generation", BMW continues to invest in top-notch testing and verification capabilities in Shenyang. Nearly 30 professional test benches in the Shenyang R&D Center provide rigorous verification for the reliable operation of the sixth-generation powertrain.

It is worth mentioning that BMW has invested heavily in building the industry's first composite EMC (electromagnetic compatibility) laboratory. With the deep integration of electrification and intelligent networking, the complexity of the electromagnetic environment and the risk of interference are growing exponentially. This laboratory, which has both intelligent networking and electromagnetic compatibility testing capabilities, has laid the foundation for the electromagnetic safety performance of the "new generation" models that far exceeds industry standards. These heavy investments in hard power are the most powerful silent declaration of BMW's quality commitment.

Building a “Quality Community”

Taking root in China and deeply integrating into the local innovation ecosystem are the key fulcrums of BMW's high-quality strategy. Its journey towards the "new generation" is not alone. Taking the "new generation" as an opportunity, the cooperation between BMW and its Chinese partners has entered the "strategic collaboration 2.0 era" and jointly built an open, trusting and symbiotic "quality community".

In the field of power batteries, which will determine the future competitive landscape, BMW has worked closely with China's top battery manufacturers such as CATL and EVE Energy to jointly promote the large-scale production of the sixth-generation power batteries.

This cooperation is different from the previous supply-demand relationship. It is a deeply integrated joint R&D and joint manufacturing. The two sides share knowledge, overcome technical difficulties, and jointly build quality standards. There is only one goal: to ensure that the BMW iX3, the first mass-produced new generation model of BMW, which will roll off the production line in Shenyang in 2026, has a power heart that not only represents the top level of "China's smart manufacturing", but also fully meets BMW's strict global standards.

In the field of intelligence, BMW chose to cooperate with Alibaba, a local technology giant, to explore innovative application scenarios of AI large language models in cars. This cross-border integration has opened up a new imagination space for the future human-vehicle interaction experience, and its underlying requirements are also high standards for data security and system stability.

Meng Junlan, Senior Vice President of Technology and Production of BMW Brilliance Automotive Ltd., emphasized: "As an important part of the BMW Group's global production network, the Shenyang Production Base follows rigorously verified global quality standards. We are committed to becoming a benchmark for luxury car manufacturers." This benchmark status was achieved through deep collaboration and mutual achievement with Chinese partners in technology, standards and processes.

The temperature of quality culture

BMW's pursuit of high-quality intelligent manufacturing ultimately returns to the core element of "people". The advanced technology system is only a tool. Behind it is the concept of "quality first" that has been deeply integrated into the company's blood and has become a quality culture that everyone from decision-makers to front-line employees believe in. Every employee clearly realizes that high quality is the prerequisite for achieving sustainable development of the company, and this awareness is constantly precipitated and sublimated in daily work.

Empowering employees means empowering quality. Through continuous technical training and advanced tool support, all employees can contribute to quality improvement in their respective positions. The company also actively encourages all-staff innovation in various fields such as products, production, supply chain, and sustainable development. As of now, the total number of patents of BMW Brilliance has reached 469. These innovative achievements that shine with wisdom are the fruitful fruits of the fertile soil of quality culture.

On the road of building the "Great Wall of Quality", technology is the engine, quality is the guide, and people are always the ultimate force to control the future. When the "new generation" model of "Chinese intelligent manufacturing, global standards" drives from Shenyang to the world, it not only carries the birth of a new car, but also a declaration of a future-oriented intelligent manufacturing philosophy and quality belief.

at last

Zheng Yuanhui, Secretary General of the Automobile Working Committee of the China Consumer Product Quality and Safety Promotion Association, pointed out at the conference: "Any technological progress should be based on safety. BMW adheres to the bottom line of safety and responsibility, and has played a positive role in demonstrating and leading the high-quality development of the industry."

This evaluation points out the deep industry value of BMW's practice - in the fierce market competition, BMW chose to fight short-term profit-seeking with long-termism, resist zero-sum games with open cooperation, and calibrate the direction of sustainable development for the entire industry with its adherence to safety and responsibility.

As the global automotive industry stands at the crossroads of intelligence and electrification, BMW's practice at its Shenyang production base has given "high-quality intelligent manufacturing" concrete contemporary connotations.